Lawn Mower Carburetors: The Secret to a Perfect Cut

Introduction

Hello, my fellow lawn enthusiasts! Thoughts behind that immaculately pristined lawn in those magazine spreads.. This is more than just the grass or the mower — it is about the little engine that could, and how that tiny engine has a secret weapon: The Carburetor. Yep, that's right. Your mower will purr like a kitten, not roar as if was the king of the jungle! In that case, read on as we discuss just what these little buggers do and how you can ensure theyre always in tip-top form. Well, stick around because we are going to reveal just that!

The Secret Ingredient: Carburetors

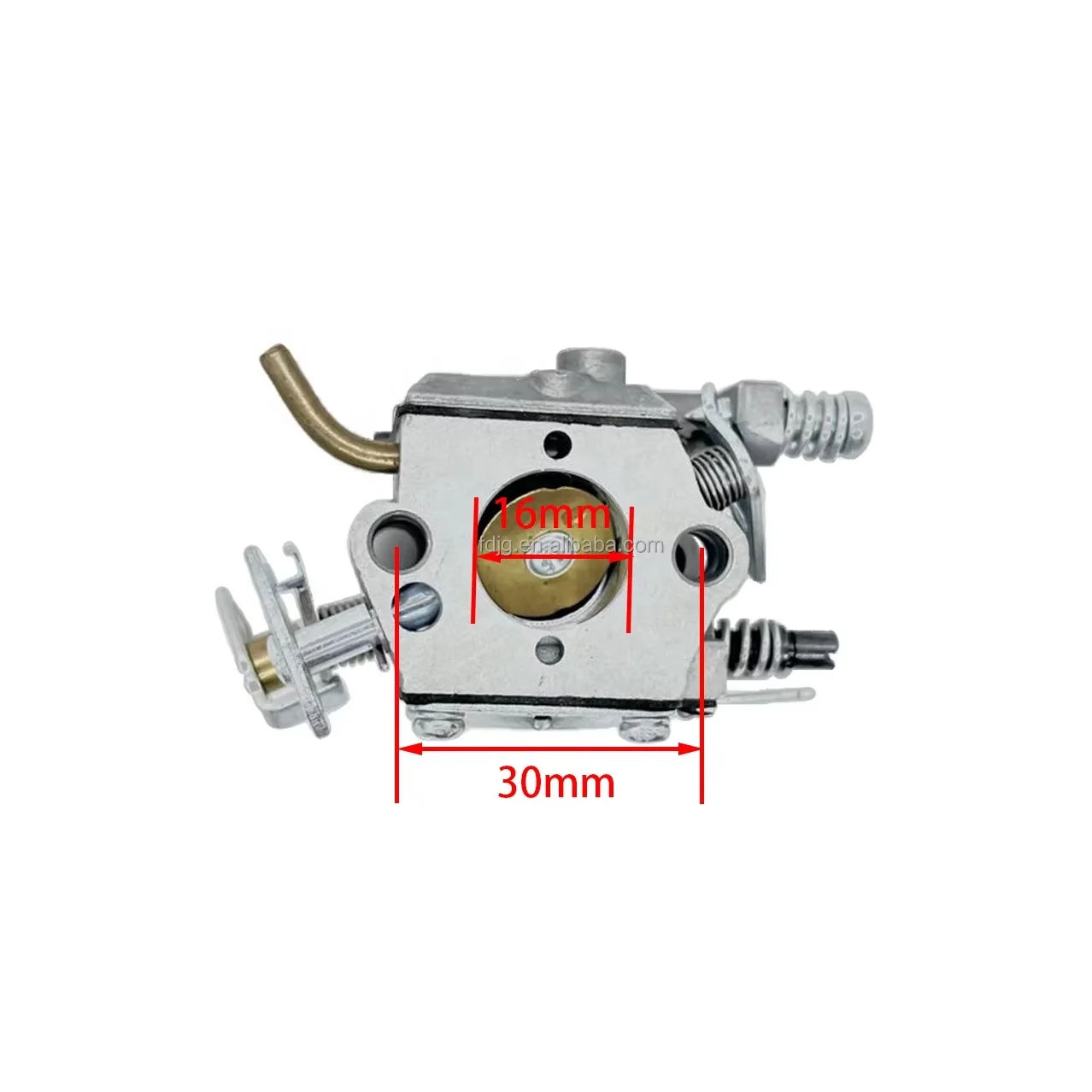

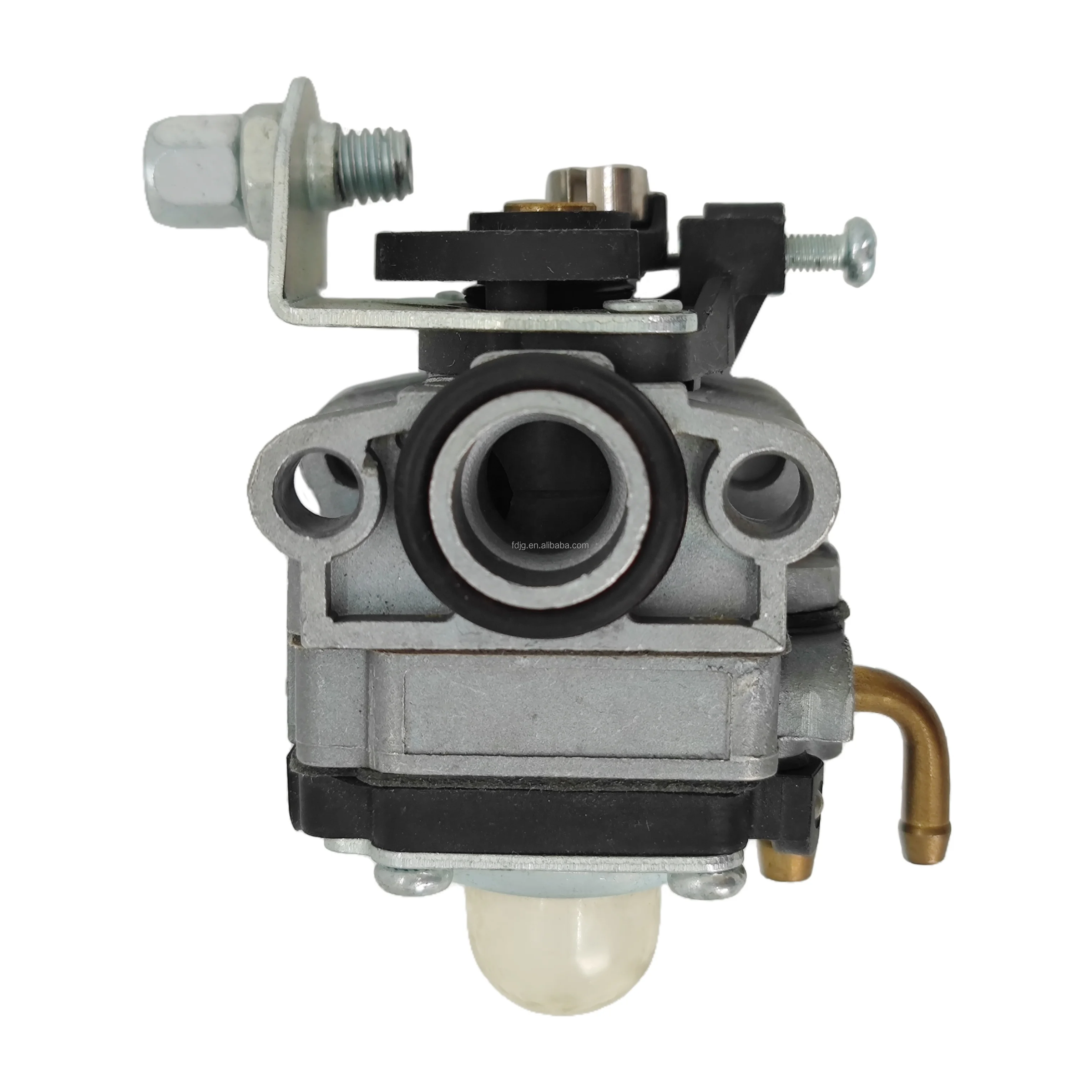

So, just what the heck is a carburetor anyway? EXPLANATIONBack to the cook in the kitchen – it is responsible for mixing all of the ingredients (fuel and air) just right, which results in an exceptional tasting dish (good engine output). A bad one has to be the worst thing possible for your lawn mower, it turns it into a costly paper weight. You will come across two-cycle and four-cycle carburetors mainly. The cycle number literally speaks to the strokes from the engine that the carburetor represents.

Then how does a carburetor operate? See it as a sort of miniature ballet with the fuel and air gracefully entwining before entering the engine. That combination is key – add too much fuel and you wind up with lazy, smokey performance. Too little, and your engine effectively goes into a liquid diet of its own, robbing it of strength and starving the engine itself for power.

Keeping Carburetors in Check for a Perfect Mow

So you got an idea of what carburetors are and do right now. But the question arises, how to manage and maintain this balance. The key to this is the routine maintenance. You cleaned up your kitchen after cooking; the same principle applies here. Your carburetor is no exception. Gunk can build up if you let your throttle body get dirty, which can choke your engine and negatively impact performance.

How do you know your carburetor is in trouble? And what if your mower is a tougher nut to crack than an uncooperative teenager? They are warning signs that your carburetor may be in need of some adjustment.

Your troubleshooting has to be like taking a cold. Runny nose or fever? Next is air-fuel mixture, clean jets and check for blockages. Or go the DIY route if you are a bit more of a handy type. However, if you're the "call-the-doctor" type yourself, feel free to call a pro.

Conclusion

And there you have it — the secret behind a flawless lawn mow (or two) is in the sound of your humming, well-oiled carburetor. It is the silent, underappreciated workhorse of lawn maintenance and we shall take a look at our grass clippings with love and positive vibes. Happy carburetor, happy lawn. Take care of it, and you will have a mower that starts at the first pull, runs like a dream, and rides through your lawn like a hot knife through butter.

There's more to achieving the ideal lawn and garden than meets the eye. Having a highly effective carburetor might exactly be what makes the difference. Now get to pulling, and keep that grass looking green with the perfect sound of your lawnmower.