Introduction Hello, my fellow lawn enthusiasts! Thoughts behind that immaculately pristined lawn in those magazine spreads.. This is more than just the grass or the mower — it is about the little engine that could, and how that tiny engine has a secret we

Introduction: The Power Behind Your Lawn's Perfect Look

Hey there, landscape lovers! Have you ever looked at that small piece of your engine that keeps your lawnmower purring like the fat cat of someone else? Oh, that's right, the carburetor. So, this might make you go "Big whoop," right? Alright, I hardly said a word about the carb, so let me do just that because it is not simply something to bolt on—at least if you insisted with Barbie Doll references from above. If you've got a lawn to mow either on the level or on steep terrain, and if you're an expert landscaper or just some Joe Blow who only wants to keep his yard somewhat trim, then a perfect carburetor will go a long way towards dictating your mowing experience.

And so we present, a carb-focused article. In this article we'll look at why it's so important to select the right cutting blade, what types are available and some of the things you need to mow over..... when making your decision. By the end of this article, you should be able to carb like a boss and your lawn will thank you.

Carburetors: The Unsung Heroes of Lawn Mowers

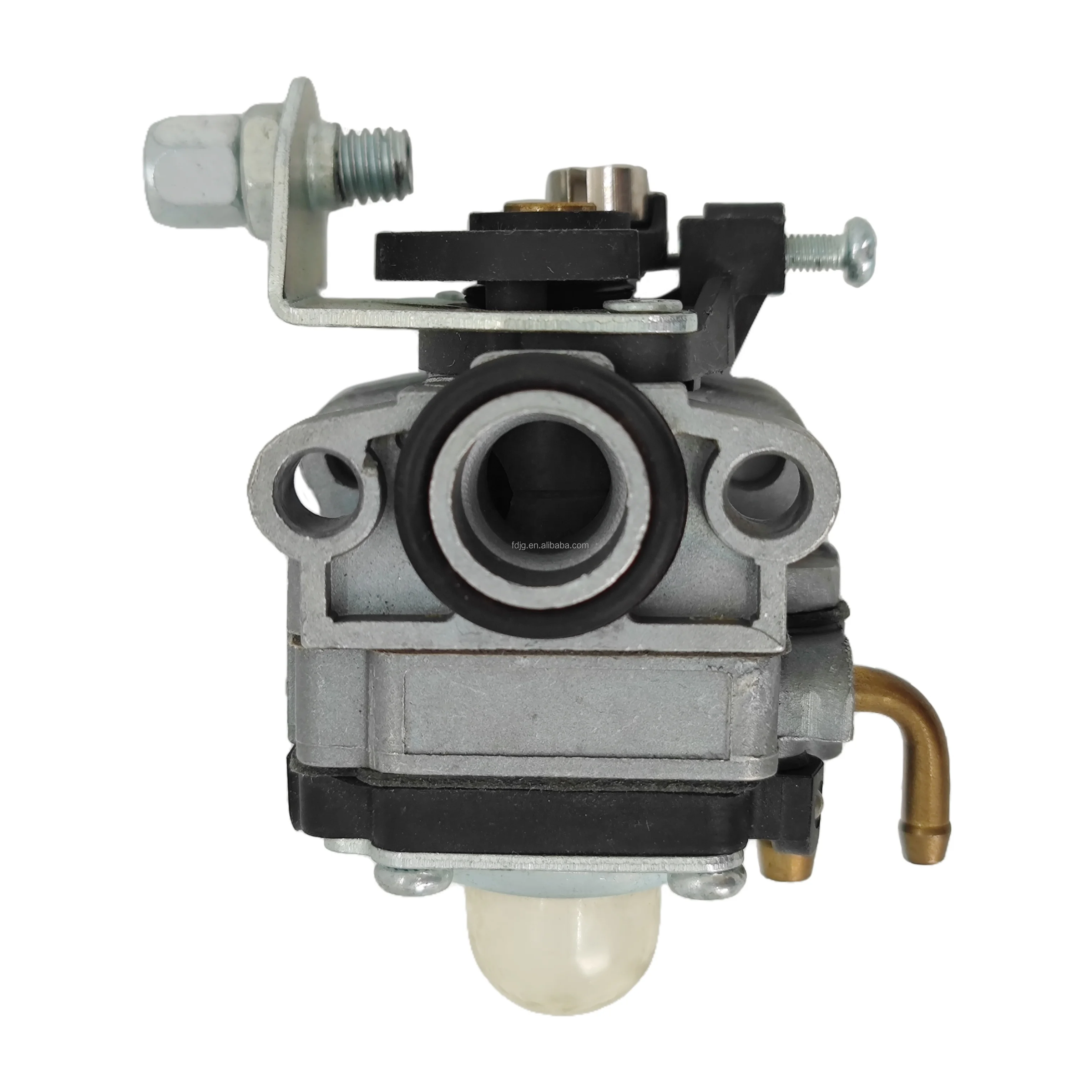

Unfortunately, the link to that site is down so I can not even link you to it, but we'll deal with our carburettor first of all. The unsung hero of your lawn mower engine, the piece that gently measures out the perfect mix of air and fuel to keep that little engine humming. There are two primary types of carburetors that you can get on the market today: two-stroke and four-stroke. The oil and gas mix is a bit hard to swallow not just for my mouth, but also the four-stroke engine is a bit heartier.

However, the engine configuration is not the only difference. The fuel you use matters too. You can do your everyday gasoline and you can get into alternative fuels, think ethanol blends. Oh, and keep in mind double check the climate you are in (temperature/altitude) as it will affect how your carburetor runs.

The Right Carburetor for Your Lawn: A Guide to Choosing Perfection

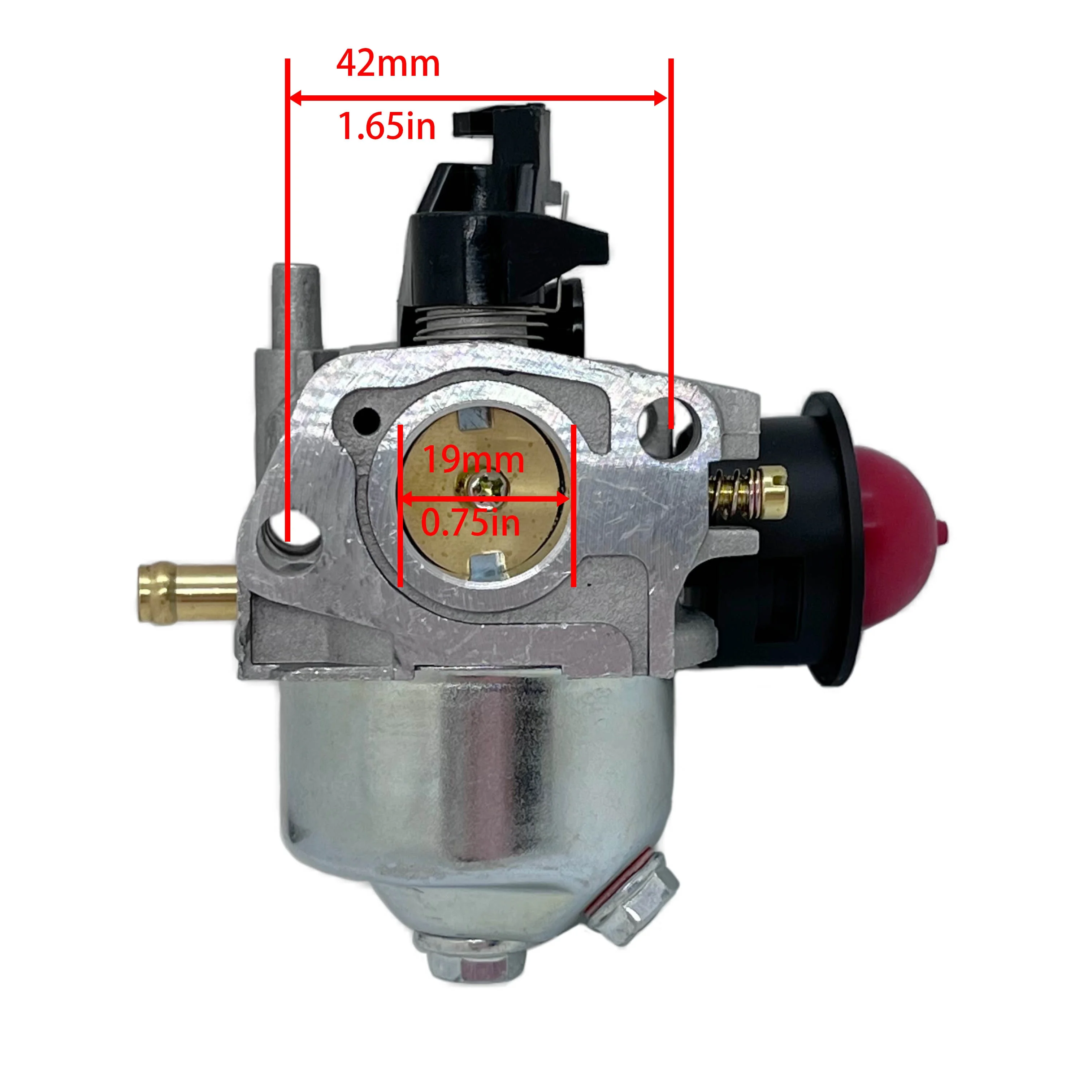

So, now I am going to discuss about the things that define a carburetor best fit for your lawn. That's an analogy, imagine you are choosing a pair of shoes (you would not put on slippers to go to a winter wedding, huh?) Same goes for carburetors. They must match your engine, fuel type, and the geography you work in.

However, compatibility is not the only factor at work. You should also consider how frequently you will mow, and how much money you want to spend! Types of carburetors Carburetors range in price, and while it might be tempting to simply purchase the cheapest one, this is typically a situation where you get what you pay for. A better quality carb might be more expensive as an initial outlay but could save you in the long run with lower maintenance, and longer life span.

Maintenance and Troubleshooting: Keeping Your Carburetor in Top Shape

It's not as easy as just slapping the new carburetor on and calling it a day... No, no, no! And thereafter, the carburetor is like a lawn in need of trimming. Make sure to perform maintenance to keep it in tip top shape.

I hope that helps you look for common problems like a dirty air filter or a clog in the fuel line. If you're ever in doubt, it would be best to get professional advice. I mean, come on, an ounce of prevention is worth a pound of cure.

Conclusion: The Right Carburetor for a Picture-Perfect Lawn

Now that you know all about selecting the perfect carb for your lawn mower, So Choose Wisely. So keep in mind, this is not all about the price tag nor the name of the brand. It is all about finding what works for you, personally.

The right carburetor can make all the difference, whether you are mowing residential lawns or tackling commercial properties. Well, then feel free to take your time and decide! This will certainly make you the talk of the neighborhood with a lawn spick-and-span, and you its under-the-sod hero.

Now, get out there and make sure your carburetor is the perfect one for your kind of grass. And so will your back if you have a self-propelled mower.