Generator Carburetors: The Key to Optimal Power Output

Introduction: The Power Behind the Scenes

Hey there, power enthusiasts! Did you ever stop to consider how your generator keeps purring and giving the voltage required by those important appliances when all power is lost? Indeed: I am speaking of the unsung hero of power production, generator carburetors. These mechanical wonders are the secret to the best power output possible, and in this article we'll discuss exactly what they are, how to keep them working well, and where they can be taken in the future of energy.

Understanding Carburetors: The Heart of the Engine

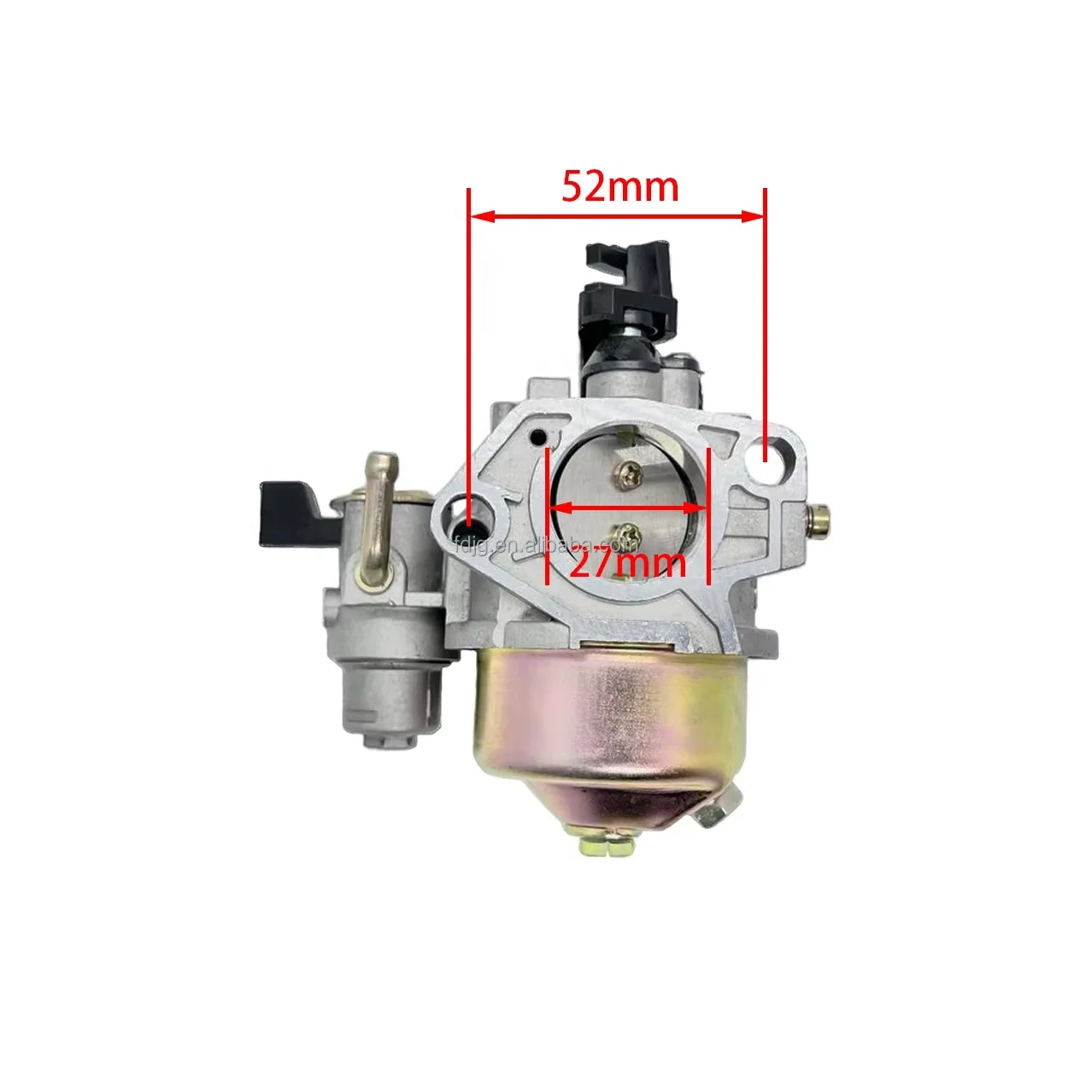

Well then, what is a carburetor? As if a chef combine ingredients to make a dish with picture prefect proportions; In much the same way that you need food and water to survive, a carburetor provides your generator engine with food (fuel) and air to make it run correctly. So, what are carburetors you ask? well, here we go-analysis 1: Lets have a look at different types of carburetors-

Single Barrel – Think of a single solo artist with a one voice: this is the basic form, used for engines that are on the smaller side.

Twin Barrel: Think of this as a pair singing in harmony—this type is for medium size engines and features two feeds for more power.

Multiport: Like a full choir; for larger engines, consists of many paths where fuel and air can come together.

Most importantly, the carb controls air fuel ratio. Overdo, and you'll have an underpowered engine. Struggle to little of communication bandwidth, much like wanting to run a marathon on an empty stomach -no way!

The Role of Carburetors in Generators: Balancing Act

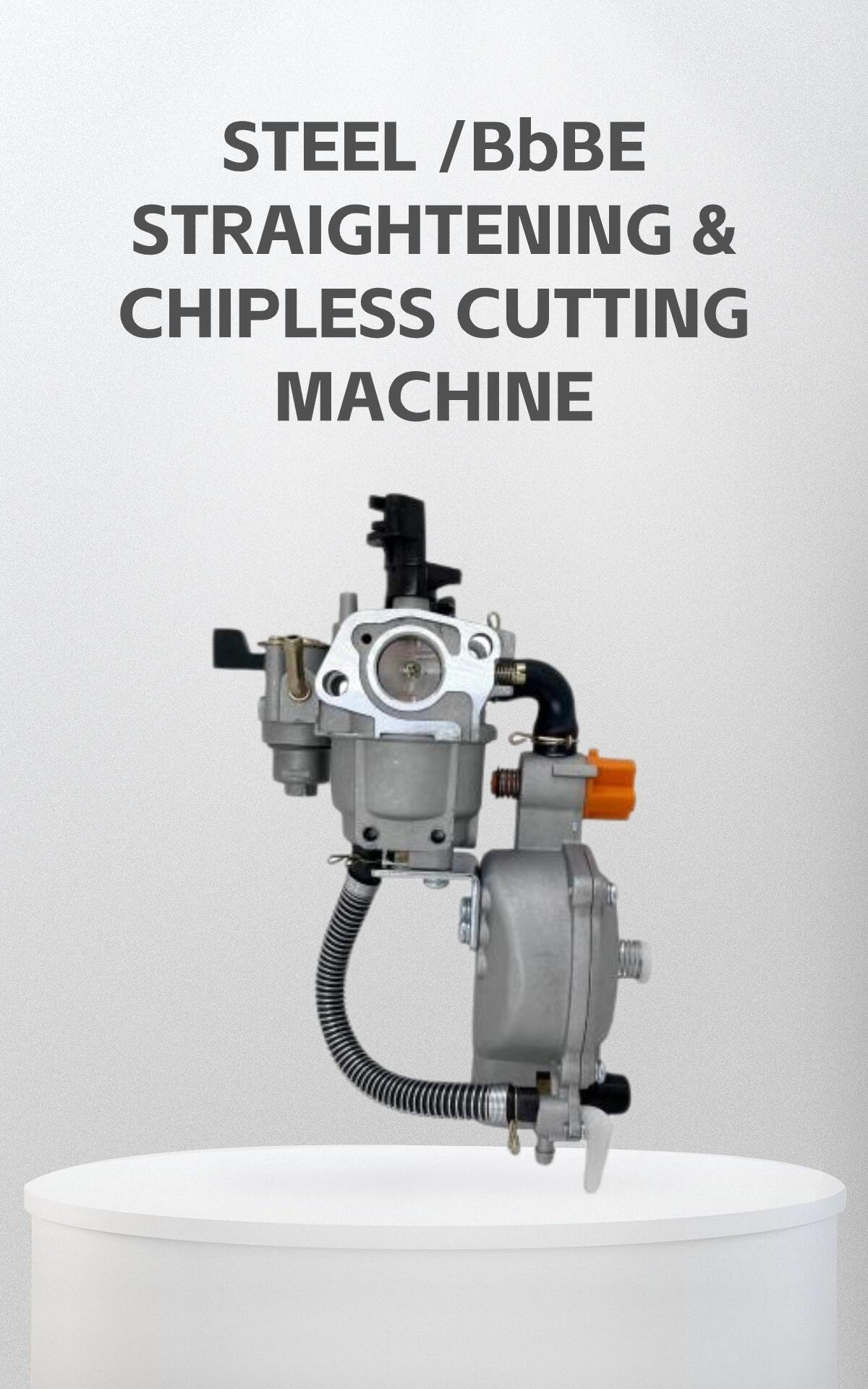

When it comes to generators, a major part of the lead role is played by carburetors. These are key elements in providing the best air-fuel mixture needed for engine efficiency and performance. However, a carburetor's just one part of the fuel system. It was a part of a team, and if not looked after, it could disrupt the rest of them.

An easy comparison is, if you've ever had a faucet that was running fine and then became clogged, how did the water flow? This also goes for a carburetor as well. The clogged filter may contribute poor fuel distribution leading your generator to sputter or stall. Maintenance And Care: This is where maintenance takes place, with both cleaning and tuning working to keep your generator running like new.

Enhancing Power Output through Carburetor Optimization: Fine-Tuning for Success

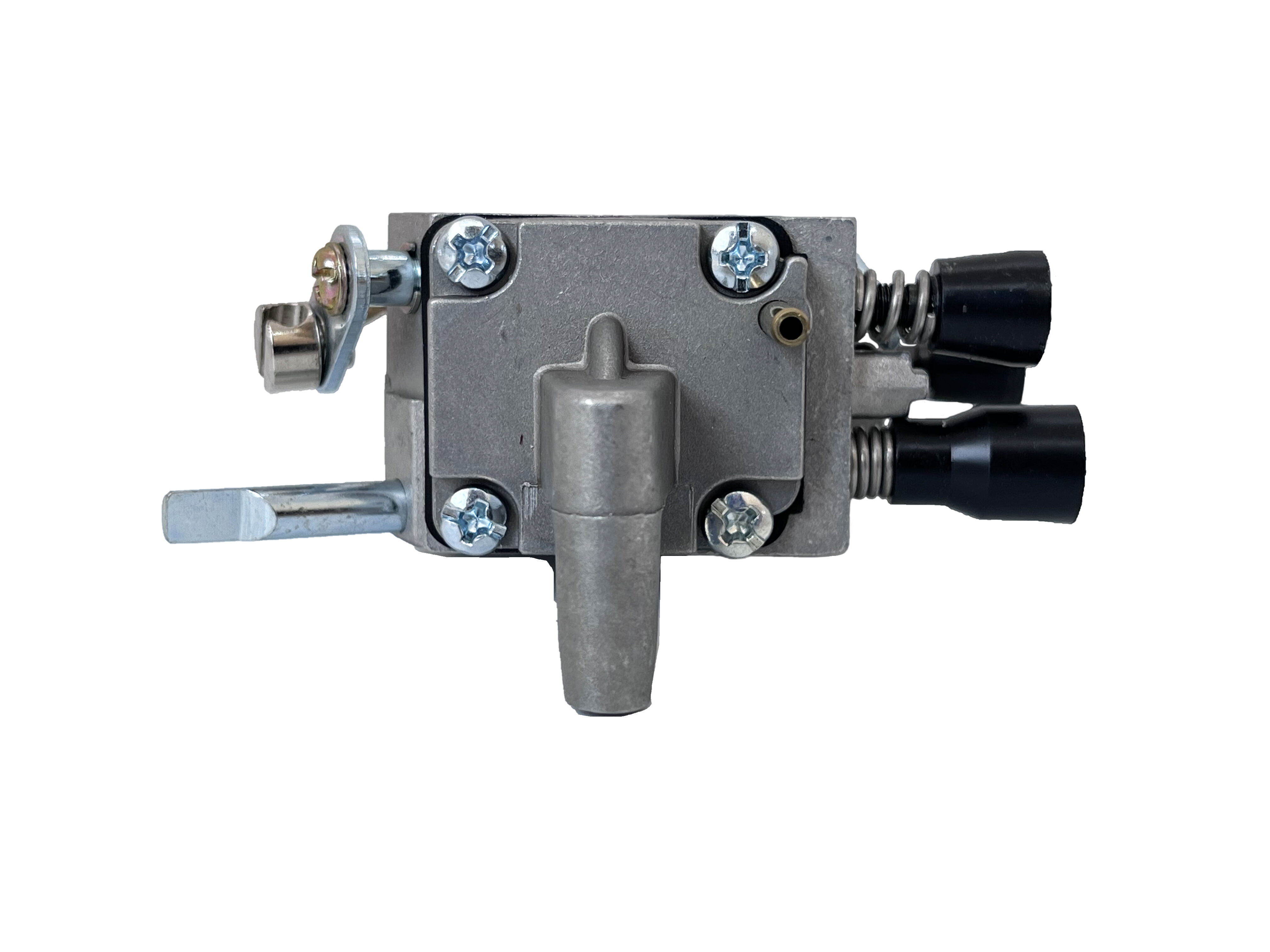

And now, we will discuss on getting the maximum out of your generator dressed up to nines. This has to do with your carburetor adjustments. You can dial the air-fuel mixture in even more by playing with the jetting and needle, getting it perfectly adjusted to make as much power as possible. Like tuning the strings on a guitar to perfectly find that note.

An even larger-7.5-liter version of the V8 is also available, along with an optional air intake modification that improves efficiency. Think of opening a window on a muggy day — it brings in fresh air and eases the room. Likewise, your generator can be improved by allowing more air intake to enhance its performance.

Conclusion: The Unsung Hero Deserves a Spotlight

In summary, generator carburetors are the unsung heroes of how your generator works. Not only do they help the engine to be more efficient, they also contribute greatly towards the progress of generator technology. The next time you flip a switch and start your generator, tip your hat to the carb. The unsong hero, time to give him his due and remind us how regular upkeep and the needed safety measures are so important.

Stay tuned for more power generation tales and be sure to feed your carburetor well. After all, happy carburetor equals happy generator!