Chainsaw Carburetors: The Heart of Your Power Tool

Introduction

Hey there, tool enthusiasts! Ever wonder what makes your trusty chainsaw roar to life and whittle down trees like a hot knife through butter? Of course, it is not magic, but a small yet powerful thing called carburetor So without further ado, we're going to get started with chainsaw carburetors — yes, that's right, the heart of your power tool. If you are a pro or just get into chainsaws, carburetors is going to be something you need to know if not go near. With all that being said lets start our journey by discussing the now chainsaws and importance of chainsaw in different industries and use of carburetor. Make sure to stick around we have a lot of lessons to get through.

The Carburetor: The Unsung Hero of Your Chainsaw

That time you went to start your chainsaw on a cold morning and it started, but sputtered and coughed… ever have that happen? Or, perhaps you have felt that ominous sensation when your chainsaw just won't kick up to as powerful as you require. Its moments like these where you learn you the value of a good running carburetor. Carburetors are the chefs in the kitchen mixing your engine's drink and making it chug even harder. Then, with their powers combined in this pre-packaged trio, they make sure your chainsaw has all the Trump Cards it needs in power/efficiency/responsiveness to get the job done.

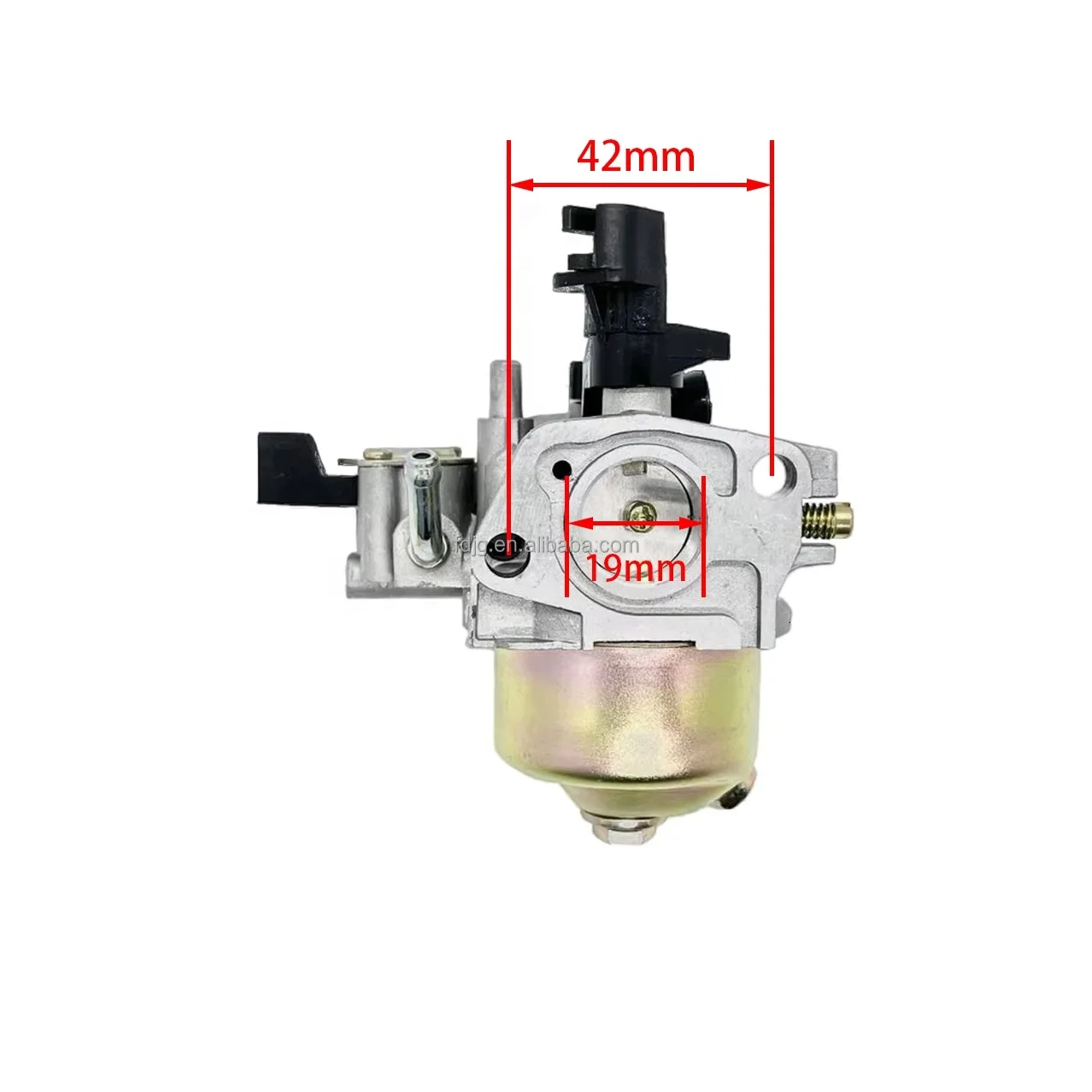

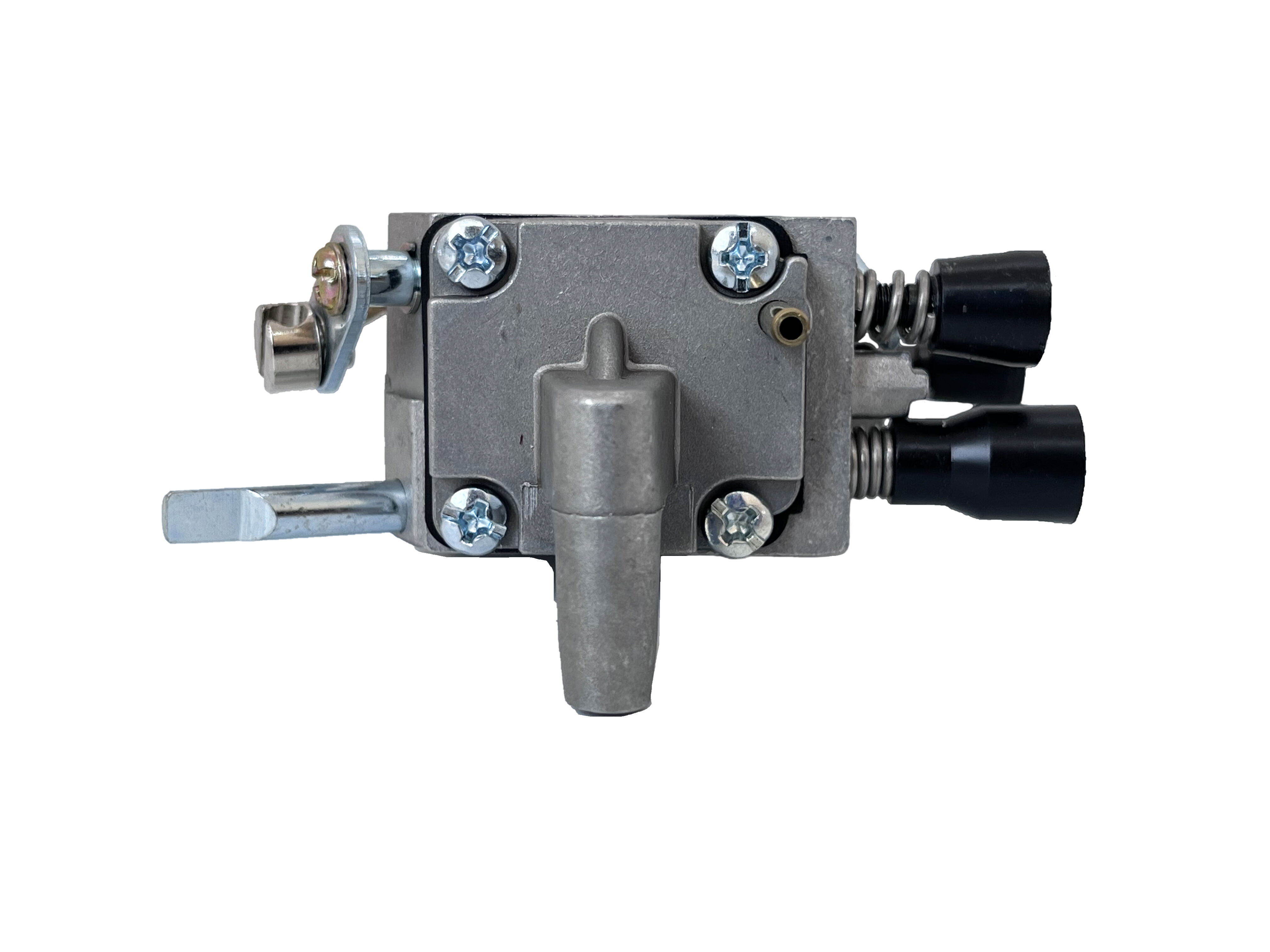

Now, let's talk types. All carburetor styles available in the market such as flat slide, picturing, Progressive carburetors. All of them have their own benefits and suited for different chainsaw brands and models. Because inside that black void of mixed fuel are float bowls and jet needles, main jets and emulsion tubes, air screws, choke systems -- all working in concert like a finely tuned orchestra to produce the proper balance between fluid gas and gaseous air.

Keeping Your Carburetor in Tip-Top Shape

Now, right or wrong, your carburetor is the main event…but even a star role needs some maintenance. Cleaning and inspection must be done on a regular basis, and carburetor adjustment comes with the territory of just like tuning a musical instrument — precision is required, as well as sharp hearing (or in this case sight). Special attention in tuning for an idle will require the air screw and choke system adjustments to allow a motorcycle to have either a smooth idle or an utter sputtering mess.

However what about when things are not going right? Some of the problems you may face include flooding or dirty fuel,or an improper fuel mixture Worry not, we have your back with a few quick remedies for you to fix it and get back into the game right away. Now granted that only goes so far, and if you're looking to elevate your chainsaw performance, carburetor upgrades are just the solution. Well discuss the advantages and which upgrade is right for your gun.

Real-World Impact: Carburetor Stories

But real talk: Check out our case studies/real-world examples that'll provide you with a better understanding of the difference carburetor maintenance and upgrades can have. From rags-to-riches tales to mistakes made and lessons learned, this is a collection of field stories that reveal knowing your carburetor can be the difference between smoothly running through tasks or combating maintenance hiccups all day.

Conclusion

And there you have it – a quick glance into the world of chainsaw carburetors. From seeing what a carburetor does and the most typical types to maintaining peak performance, you’ve read it all. As you’ve just learned, a well-cared-for carburetor is crucial to maintaining a strong, high-performance chainsaw. When you’re once more tearing throughout the neighborhood or immersing yourself in the forest, chewing aside wood one tree slice at a time, pay respect to your chainsaw’s unsung hero, the carburetor. Your tool’s heart is saved by it, and if you treat it with a little respect, this valuable jewel will keep your chainsaw working like new. Well, good cutting!