Optimizing Performance: Chainsaw Carburetor Maintenance

Introduction

When it comes to forestry, landscaping and outdoor industries as a whole chainsaws have been the go-to tool. Despite their toughness, the strength of these machines is substantially dependent upon a tiny but crucial part: this is where carburetor comes into play. A carburetor is responsible for combining air and fuel in the accurate mixture ratio which helps ignited within engines. It is important to perform routine maintenance on the carburetor so that you can achieve optimal performance, efficiency and longer life of your equipment In this piece, you learn why to maintain the chainsaw carburetor and how can your precious saw be on top of its performance.

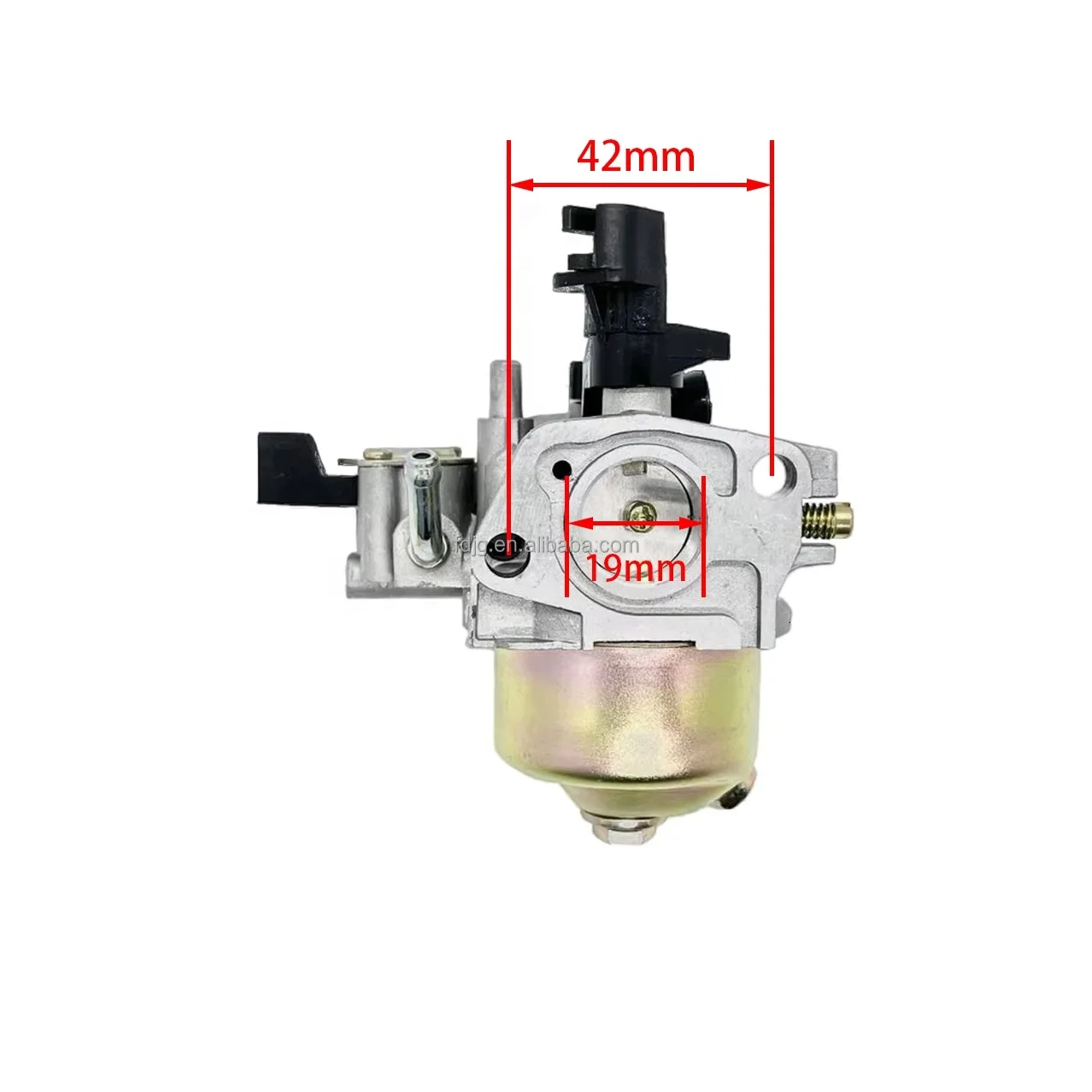

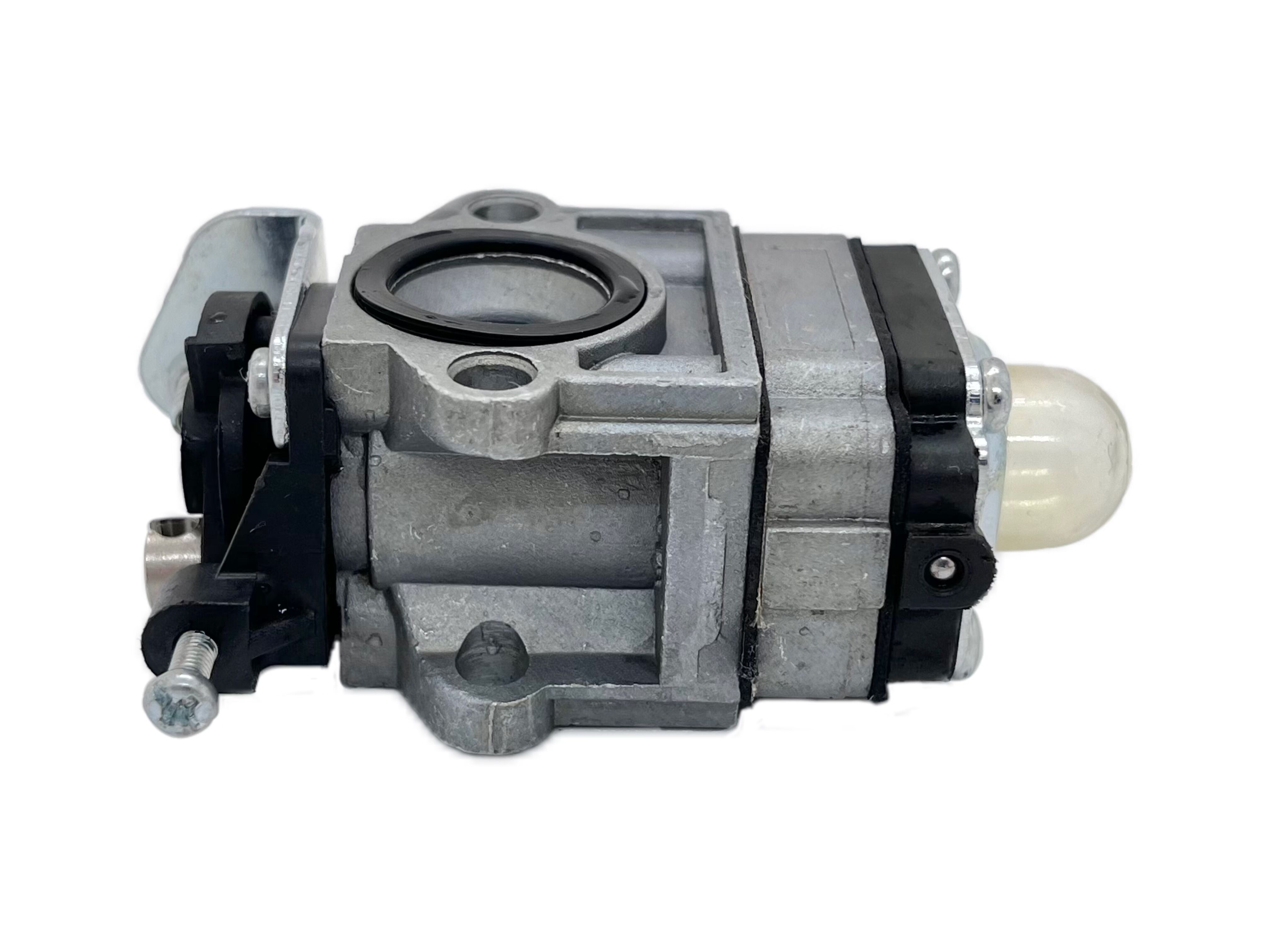

Chainsaw Carburetors Explained

A carburetor connects an intake of air to the fuel tank and works for a chainsaw by pulling in air into a chamber, mixing it with gasoline from your gas container. Then the engine's intake passage injects this air-fuel mixture into its cylinders, compresses it and ignites to generate power. These include throttle body, jets and float chamber which work together to supply the correct mixture for combustion in an engine. This ingredients must be in a fine mix; too rich might flood your machine, and to lean can cause poor performance or damage the engine.

Why It's Important to Look After Your Carburetor

A carburetor that is either dirty or not functioning properly can drastically reduce a chainsaw's power output. Many such symptoms can be directly attributable to a carburetor that has been allowed to fall into disrepair. Regular maintenance will help to avoid these problems and ensure the chainsaw works efficiently. But beyond that, taking the time to maintain a carburetor can increase longevity of the chainsaw and save users from pricey repairs or early replacements.

Basic Carburetor Maintenance Routine

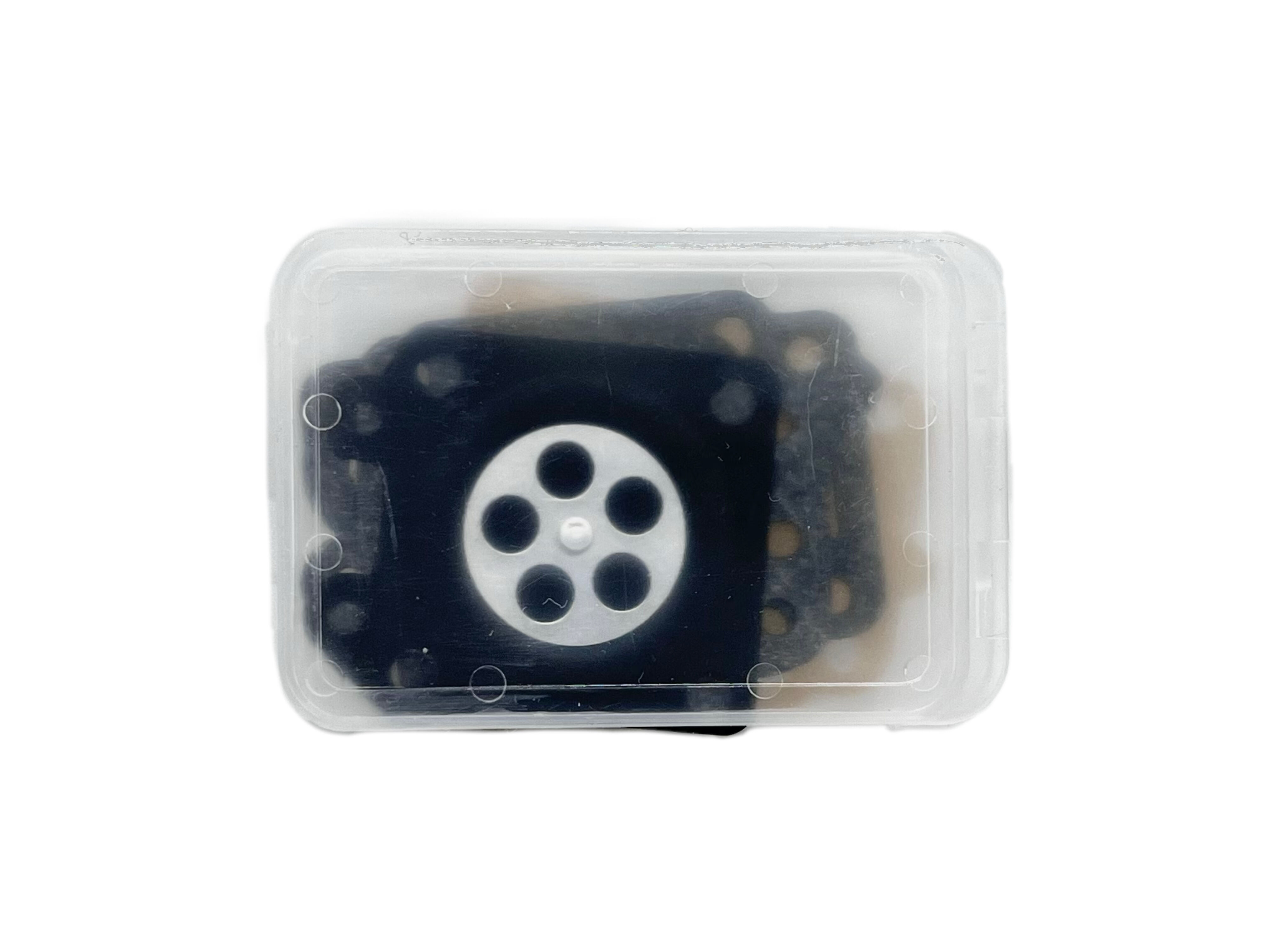

The most basic way to do this is by cleaning the carburetor. This means to tear down the carburetor, check all parts for wear and damage and clean the jets & passages. The air-fuel mix screw that adjusts the amount of fuel in the mixture should also be check and set where needed. Also, the air filter needs to be checked and replaced if it is plugged up (a dirty or clogged-up of an airstream will reduce airflow which plays havoc with carburetor performance).

Along with the maintenance techniques, this course will walk you through concepts and practices to maintain smooth operation of your data center.

For the more experienced, here is a list of some common carburetor issues and fixes. Cleaning the Carburetor and setting air–fuel mix is can be enough to fix a carb problem of either hard starting or flooding. If this doesn't sort the problem, then you might want to get a pro in or have your carburetor replaced. Quality replacement components are also helpful to the longevity of auto carburetor and chainsaw overall performance.

Tips for Different Operating Conditions

Altitude and Temperature also can alter the performance of a carburetor In high-altitude operations, some adjustment to the carburetor settings is necessary for proper combustion. There can also be problems with cold-weather starting and you might need to fiddle with the carburetor a bit to get it just right when weather is cool.

The Importance of High-Quality Fuel For Carburetor Upkeep

The type of fuel being used within a chainsaw can also affect the way it runs, even causing detriment to its carburetor. Clean Fuel: By using fresh, clean gas you will help avoid clogs and other problems in your carburetor synchronize. Storing the fuel properly and even adding a stabilizer can also help keep the carburetor functioning well. Some Types Might Temperamentally Season Specific Fuel Use — As Well as How It Is Stored Continue Reading Show full articles without "Continue Reading" button for hours.

Conclusion

The carburetor is one of the most crucial parts within a chainsaw, and its upkeep is fundamental for operating at peak performance. By knowing the principles of carburetor operation, regularly carrying out standard maintenance tasks and even recognizing more advanced troubleshooting strategies chainsaw users are able to keep your tool operating like a well-oiled chain (pun intended). Taking care of the carburetor, which requires investing our time not in vain since it prolongs the service life — without a chainsaw for longer than necessary is an unpleasant sight.