Choosing the Right Generator Carburetor for Your Needs

Introduction

It becomes the most center components during turbine process because it maintains equilibrium with air / fuel blend small applications for correct combustion of course. Fix your generator carburetor today and spend less time wasting energy than others beneficiaries as well all that are currently around you! Unless you are satisfied with performance, reliability and fuel economy the right carburetor must be selected for your generator too. In this post, we will show you what to look for and the different types of carburetors on offer as well as how upkeep is a key factor in determining which generator carburetor fits your bill.

Carb Basics Explanation

The main goal of the carburetor is to have air fuel vapor mixture in such proportions that are ignited with spark plug effectively for engine performance. This air is mixed with fuel and then delivered to the engine's cylinders, where it gets compressed before being ignited. The design of carburetors may differ, but their basic function is simply to allow the engine work at its best.

Selection Factors for Carburetor

Here are some of the things to need consider when choosing a carburetor for your generator:

Engine specifications: The engine size and power needs of your generator will play a big part in what kind o carburetor that you need. Lastly, the kind of fuel (gasoline diesel, natural gas etc,) being used will also make a difference in carburetor selection.

Operating conditions: Factors such as temperature, altitude and humidity can affect how well the carburetor's work. Another important consideration for generator specification is the actual use of when it would be running (i.e. constant or issue).

Maintenance: Ease of cleaning and adjustment, availability of parts, etc. should be kept in mind while selecting carburetor

Carburetors For Generators(Device)

As you can see, there are various types of carburetors made for generators;

Float-type carburetors: These are the old-school carbs with a float that sets fuel level. They are well-equipped for most standard office content but might need more regular maintenance.

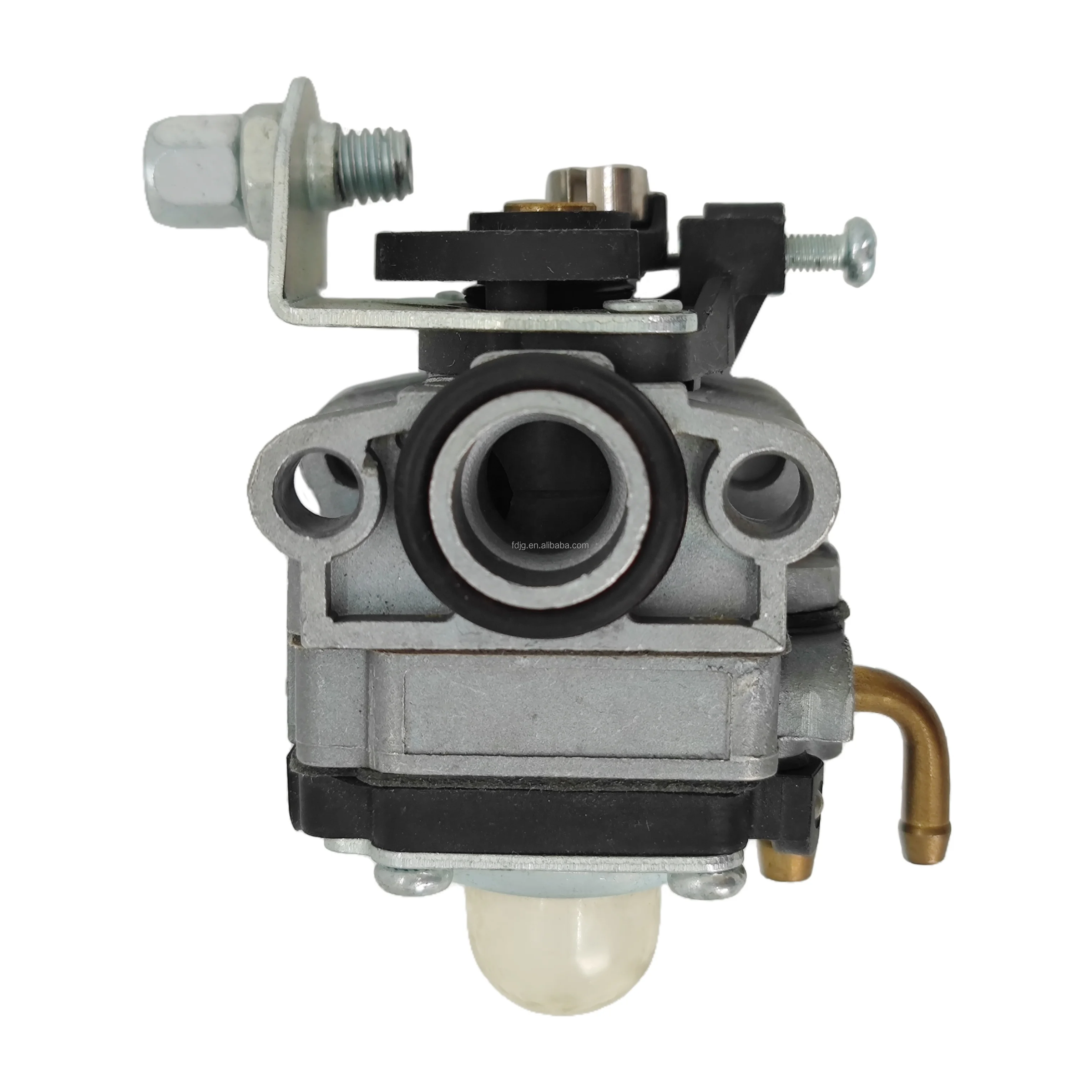

Diaphragm-type carburetors: These use a diaphragm to modulate fuel flow, and they outperform float-type carburettor. However, these tend to be more susceptible to atmospheric altitude or temperature changes.

Electronic fuel injection systems : Recently developed Systems which allow exacting control of the Fuel an make for a more efficient engine that traditional Carburetors. Perfect for use cases where performance is consistently high and not cost-efficient out of the box.

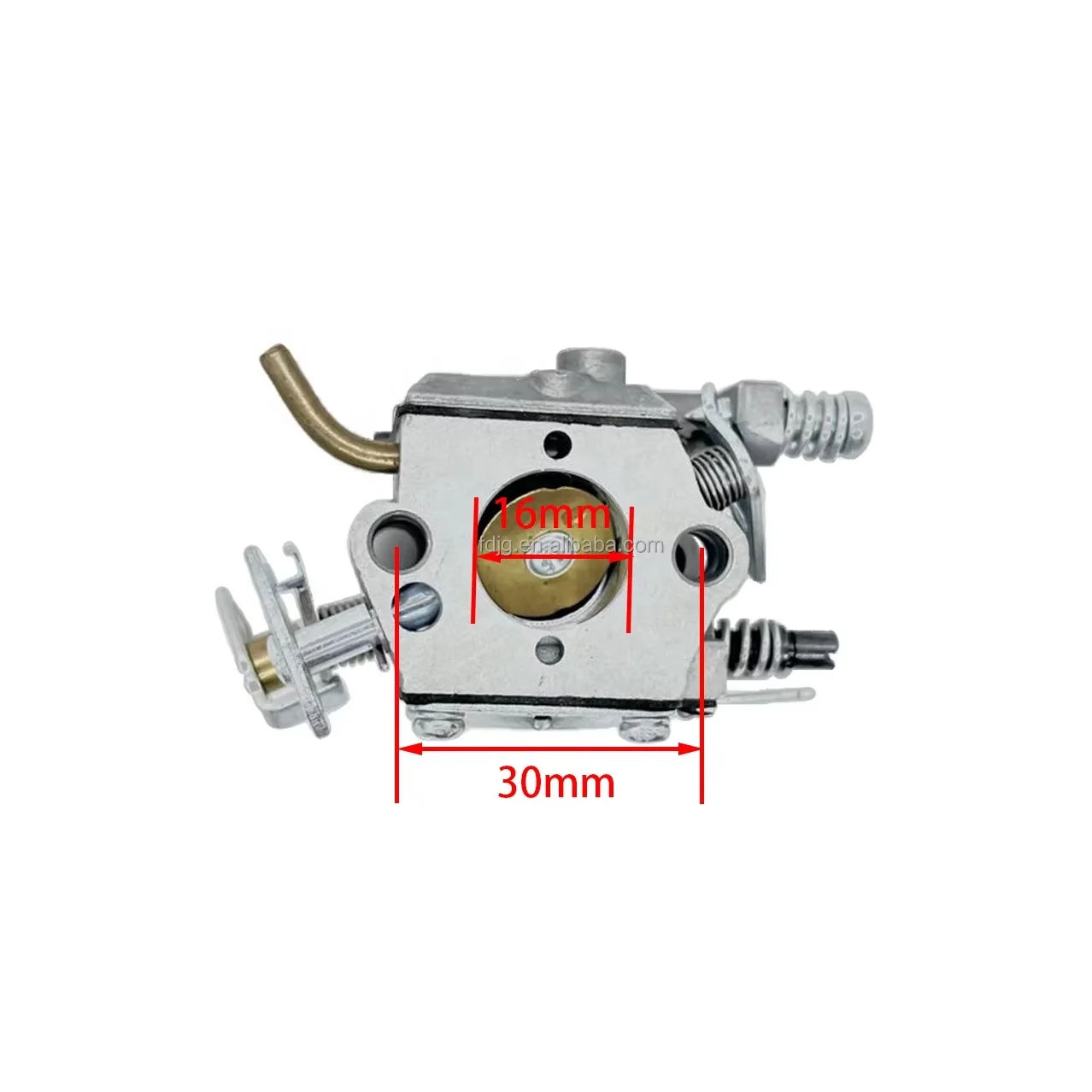

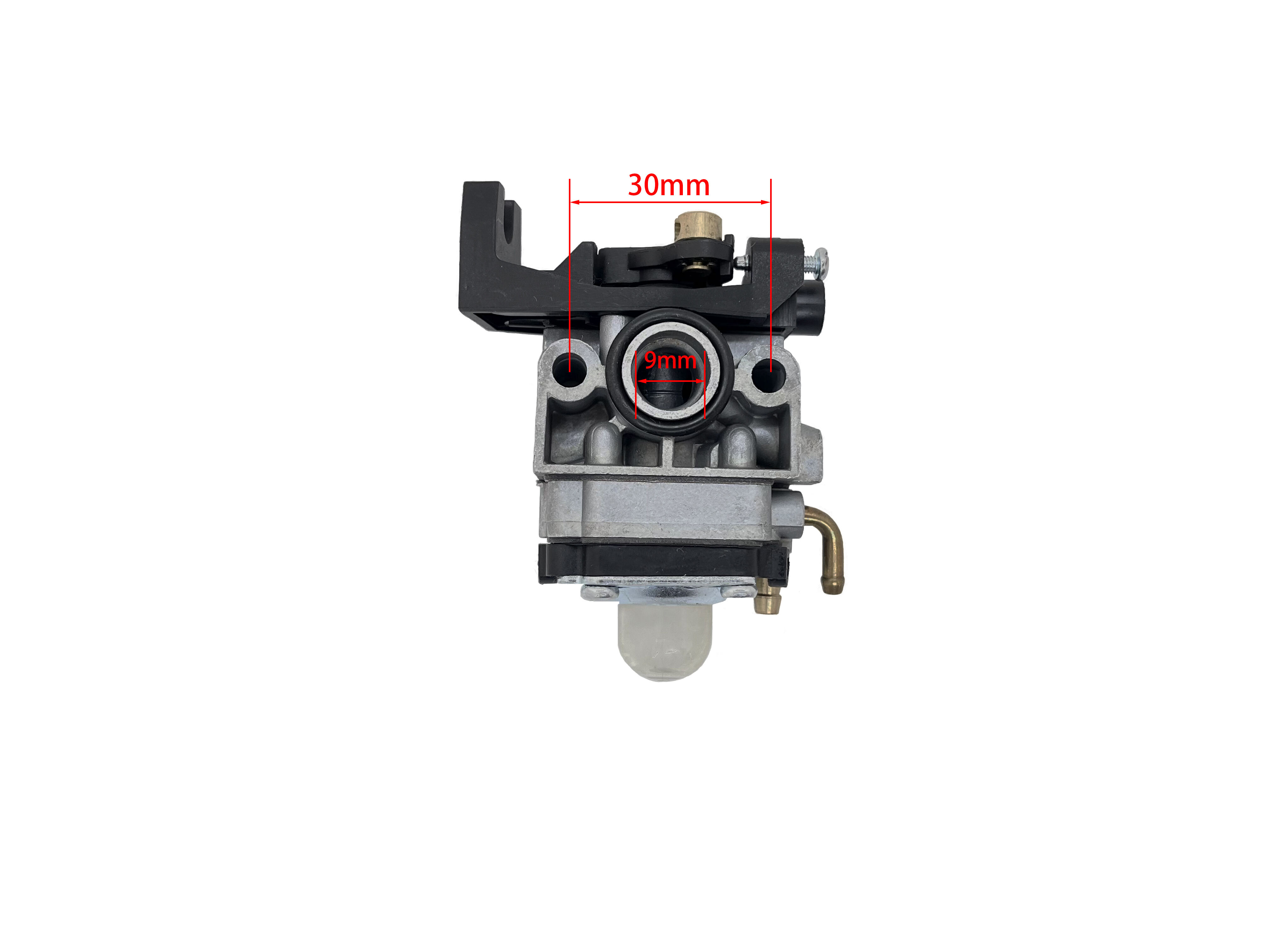

Correctly equipped carburetor according to your generator

For peak performance, it's critical to size the carburetor correctly for the engine in a generator. If the carburetor is too small, it will not be able to supply enough fuel vs. an oversized on which can contribute toward poor fuel economy and emissions….. When choosing a carb, you need to take into account the load characteristics of your generator and its duty cycle.

Maintenance and Treasure Hunting

Your carburetor will last long and perform at its best with good maintenance habits. Using carb cleaner and seeing if there is any dirt floating around in the fuel bowl will indicate that your jets are not working right. You should clean and check for blockages to see what exactly went wrong with each jet, after also cleaning out your float level at its correct adjustment. Most common problems include: flooded engine, idle issues – many of which can typically be traced back to the carburetor and will depend on what type has been installed so specific types of this unit require special troubleshooting.

Things to Keep in Mind About Environmental and Regulatory

And depending on the carbide being used, it should be taken into account with regard to emissions and regulations. The emission standards could affect the carburetor choice, and improving fuel efficiency would help lower overall generator emissions. Make sure your generator installation meets local codes

Making the Final Selection

Balancing out the Features of Each Carburetor Type The true cost Owning these classic carbs and Professional Advice Your engine demands the right carburetor to generate power consistently and with little downtime.

Conclusion

Correct selection of the generator carburetor is important for continuous power generation and wonderful performance & efficiency effect on a particular generator. This way you can accurately decide by looking into engine specifications, operating conditions, maintenance requirements and environmental considerations. You will get used to your new carburetor, and you will benefit every time by spending extra time selecting the right carburetor for a continuous power band in nursing.