Enhancing Generator Efficiency Through Mechanical Precision

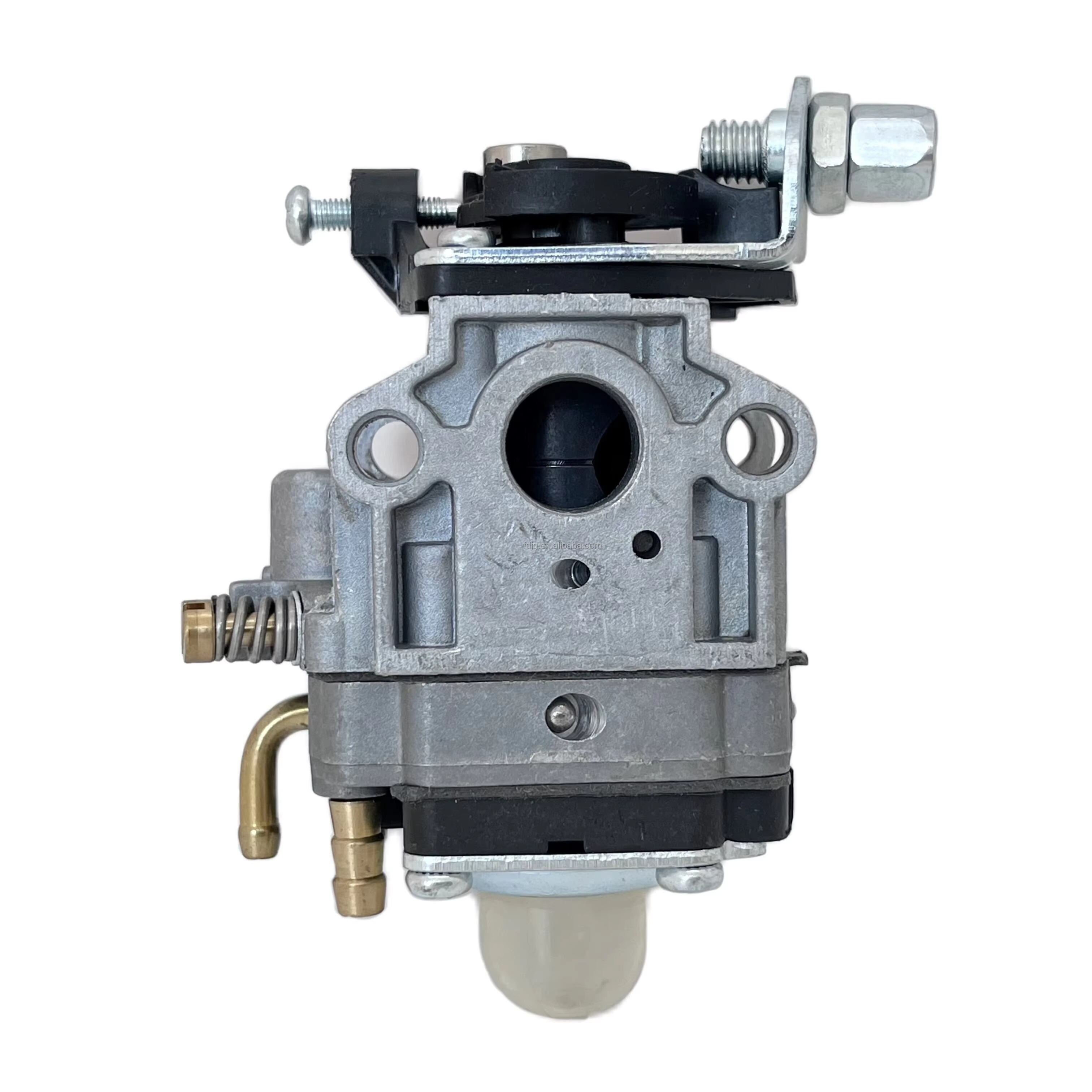

The efficiency of any gasoline-powered generator depends not only on its engine size or fuel quality but also on the performance of its carburetor. As a core component in internal combustion systems, the carburetor plays a vital role in regulating the air-fuel mixture, ensuring that the engine receives the optimal blend for combustion. When properly tuned and matched, the right carburetor can significantly improve generator responsiveness, fuel efficiency, and overall operational stability.

For generators used in home backup power, construction sites, or mobile applications, reliability is non-negotiable. A poorly functioning carburetor can lead to hard starts, stalling, surging, or high fuel consumption. Investing in the correct carburetor and maintaining it properly can transform how well your generator performs under various load conditions.

Core Functions and Influence of a Generator Carburetor

Managing the Air-Fuel Ratio

At the heart of a generator's engine operation is the air-fuel ratio. A carburetor is responsible for blending air and gasoline in the correct proportions before it enters the combustion chamber. If the mixture is too rich, it leads to inefficient burning and excessive carbon buildup. If it's too lean, the engine may run hot or misfire.

The carburetor adjusts this ratio based on throttle input, atmospheric pressure, and engine speed. A finely tuned carburetor ensures that the generator runs smoothly whether it’s powering a single appliance or running at full capacity.

Engine Performance and Stability

A carburetor directly affects engine idling, acceleration, and power output. Stable engine operation depends on precise metering of fuel at all times. When a generator’s carburetor is in good condition and properly calibrated, it provides consistent RPMs under load and smooth transitions between power states.

This consistency is crucial in settings where voltage drops or surges can damage sensitive electronics. A reliable carburetor maintains combustion efficiency, which in turn delivers steady power output across various usage scenarios.

Key Features of a High-Quality Generator Carburetor

Material Durability and Corrosion Resistance

Not all carburetors are built the same. Premium models use materials like zinc alloy, anodized aluminum, or corrosion-resistant brass components. These materials extend the lifespan of the carburetor by reducing the impact of ethanol-blended fuels, moisture, and temperature fluctuations.

Choosing a carburetor built from quality materials ensures long-term performance with minimal degradation. This matters greatly in humid or variable environments, where cheaper models may corrode or clog more frequently.

Precision Machining and Jet Configuration

A well-designed carburetor features precisely machined jets, float bowls, and throttle plates. These elements determine how much fuel and air enter the combustion chamber under different conditions. Models with adjustable jets offer the ability to fine-tune performance based on altitude, climate, or fuel type.

More advanced carburetors may also include high-speed and low-speed jets to optimize performance across different engine RPM ranges. This flexibility makes it easier to adapt the generator’s output to specific needs without compromising fuel efficiency.

Selecting the Right Carburetor for Your Generator

Matching Carburetor to Engine Displacement

The first consideration in selecting a carburetor is compatibility with your generator’s engine size. A carburetor designed for a 200cc engine won’t work effectively on a 500cc model, and vice versa. Displacement-specific carburetors ensure the correct volume of air-fuel mixture reaches the combustion chamber.

Check manufacturer recommendations or engine manuals to find the proper carburetor match. Incorrect sizing can lead to underperformance, starting issues, or premature wear of engine components.

Considering Application and Runtime Demands

Generators used for emergency backup may have different requirements compared to those running construction tools or outdoor events. A carburetor with an automatic choke may be ideal for intermittent use, making cold starts easier without manual adjustment.

Conversely, commercial generators may benefit from carburetors designed for extended operation, featuring reinforced diaphragms and filters that resist contamination from fuel deposits or dust-laden air.

Maintenance Practices for Long-Term Carburetor Performance

Cleaning and Jet Inspection

Over time, dirt, varnish, and fuel residue can accumulate inside the carburetor. Periodic cleaning is essential to prevent clogging of jets and fuel passages. Use a carburetor-specific cleaner and a set of jet cleaning tools to remove buildup without damaging delicate parts.

Inspecting the jets for signs of wear or deformation is equally important. Even slight distortions can affect fuel metering and lead to poor generator performance or increased fuel consumption.

Gasket and Float Maintenance

The gasket that seals the carburetor to the engine and the internal float mechanism are common sources of operational issues. Gaskets can dry out and crack, leading to air leaks that alter the air-fuel ratio. The float, which regulates fuel level in the bowl, can become stuck or misaligned.

Replacing these components during routine maintenance can restore proper functionality. Some high-quality carburetor kits include durable gaskets and float assemblies that are resistant to ethanol and heat-induced warping.

Diagnosing Carburetor-Related Generator Problems

Symptoms of a Dirty or Failing Carburetor

When a carburetor is malfunctioning, the generator often shows clear signs. These may include hard starting, sputtering, fluctuating RPMs, or black smoke from the exhaust. Fuel leakage or a gasoline odor near the carburetor are also red flags.

These symptoms should prompt immediate inspection. Ignoring carburetor problems can lead to engine wear, wasted fuel, or even generator failure during critical usage.

Using Adjustment Screws for Fine Tuning

Most carburetors come with one or two adjustment screws—typically labeled for idle speed and air-fuel mix. Knowing how to use these allows users to fine-tune generator performance. Turning the screws incrementally while the generator is running can help optimize combustion.

Keep in mind that over-adjusting can lead to unintended consequences. Always refer to manufacturer settings when possible and use a tachometer or multimeter to monitor performance as you tune.

Upgrading or Replacing Your Generator’s Carburetor

Signs It’s Time for a Replacement

Sometimes cleaning and adjustment aren’t enough. If the carburetor body is cracked, threads are stripped, or the throttle linkage is loose beyond repair, replacement is the most practical solution. Similarly, if your generator continues to perform poorly despite maintenance, the internal fuel circuits may be compromised.

New carburetors are relatively affordable and can restore factory-level performance. Replacing a damaged or inefficient carburetor is often less expensive than dealing with engine repairs or prolonged downtime.

Benefits of Aftermarket or OEM Carburetors

Aftermarket carburetors can offer performance improvements, particularly when they are designed for increased airflow or high-efficiency combustion. Some models are optimized for specific conditions such as high altitudes or low temperatures. OEM carburetors, on the other hand, ensure exact compatibility and reliability.

Choosing the right type depends on your usage priorities—whether it's extended runtime, improved fuel economy, or simplified installation. For critical applications, many users stick with OEM carburetors to maintain consistent performance and warranty coverage.

Fuel Compatibility and Environmental Conditions

Impact of Ethanol and Fuel Stabilizers

Modern fuels often contain ethanol, which can degrade rubber components and attract moisture inside the carburetor. Ethanol also tends to leave behind sticky residues that clog jets and passages. Using ethanol-free gasoline or fuel stabilizers can mitigate these issues.

Fuel stabilizers help extend the life of gasoline stored in the tank or carburetor bowl, especially during periods of inactivity. These additives prevent varnish formation and keep the carburetor clean over time.

Adapting to Seasonal Changes

Ambient temperature affects carburetor performance, particularly during cold starts or extremely hot weather. Some carburetors include a manual or automatic choke to enrich the fuel mixture when the engine is cold. Others have adjustable idle screws that help maintain performance during heat waves or high-humidity days.

Adjustments should be made seasonally or when moving the generator between different climates. Keeping track of how your carburetor performs under varying conditions ensures uninterrupted performance.

Maximizing Fuel Economy with a Balanced Carburetor

Lean vs. Rich Mixture Considerations

Operating with a fuel-rich mixture may improve power but comes at the cost of fuel economy and increased emissions. A lean mixture saves fuel but can overheat the engine or cause knocking. Finding the balance is essential for both performance and economy.

Fine-tuning your carburetor to achieve this balance allows the generator to run longer on a tank of fuel while reducing engine strain. This balance becomes especially valuable during extended power outages or field use.

Idle Speed and Load Handling

Proper idle speed settings ensure that the generator doesn’t consume unnecessary fuel while operating without load. On the other hand, it should ramp up fuel delivery efficiently when a load is applied. A well-calibrated carburetor allows the generator to handle varying loads without surging or stalling.

Maintaining the ideal idle ensures that fuel is only used when needed. For generators that power variable appliances or tools, this dynamic response can significantly reduce operational costs over time.

Future Outlook: Electronic Carburetors and Smart Systems

Integration with Modern Generator Systems

Carburetors are evolving with electronic components that improve precision and reduce manual tuning. These "smart" carburetors use sensors to adjust fuel delivery in real time, adapting to altitude, humidity, and engine demands instantly.

Generators equipped with such systems offer plug-and-play reliability and often come with diagnostic features that make troubleshooting easier. These upgrades are shaping the next generation of efficient, automated power solutions.

Sustainability and Emission Compliance

Governments are implementing stricter emission standards for small engines. Newer carburetor designs help reduce unburnt fuel emissions and support cleaner generator operation. High-performance carburetors are often part of a broader effort to make portable power equipment more environmentally friendly.

Switching to a compliant and efficient carburetor not only improves generator performance but also contributes to regulatory compliance and environmental responsibility.

FAQ

How often should I clean the carburetor on my generator?

For regular use, cleaning every 6 to 12 months is ideal.

More frequent maintenance may be needed in dusty or humid environments.

Can I use any carburetor on my generator?

No, carburetors must match your generator's engine specifications.

Using an incompatible carburetor can cause poor performance or engine damage.

Why does my generator run rough after replacing the carburetor?

It may need air-fuel mixture adjustment or idle tuning.

Double-check gasket seals, linkage alignment, and jet calibration.

What’s better: rebuilding an old carburetor or buying a new one?

If the old carburetor has structural damage, replacement is the better option.

Rebuilding can be cost-effective if the body is intact and parts are available.

Table of Contents

- Enhancing Generator Efficiency Through Mechanical Precision

- Core Functions and Influence of a Generator Carburetor

- Key Features of a High-Quality Generator Carburetor

- Selecting the Right Carburetor for Your Generator

- Maintenance Practices for Long-Term Carburetor Performance

- Diagnosing Carburetor-Related Generator Problems

- Upgrading or Replacing Your Generator’s Carburetor

- Fuel Compatibility and Environmental Conditions

- Maximizing Fuel Economy with a Balanced Carburetor

- Future Outlook: Electronic Carburetors and Smart Systems

- FAQ