Enhancing Engine Efficiency Through Precision Fuel Mixing

In the world of generators, achieving maximum engine performance hinges on more than just horsepower or fuel quality—it also depends on the component responsible for mixing fuel and air: the carburetor. While often overlooked, a well-designed carburetor ensures optimal combustion efficiency, smooth startup, stable idle, and consistent power output. Whether used in backup generators, portable units, or construction-grade machines, the role of a carburetor is fundamental to engine longevity and operational reliability.

As more households and industries rely on generators for daily use, understanding how the right carburetor supports engine health becomes critical. From managing fuel-to-air ratios to reducing carbon buildup, the carburetor is central to overall engine behavior. Choosing a high-quality carburetor can be a strategic upgrade that leads to tangible gains in performance and efficiency.

Understanding the Role of a Generator Carburetor

Air-Fuel Ratio Optimization

The carburetor's core responsibility is to maintain the right air-to-fuel ratio. Too rich, and the engine may flood or run inefficiently. Too lean, and it risks overheating or misfiring. A precision-calibrated carburetor helps the engine run at its designed power curve while keeping combustion clean. This equilibrium ensures consistent voltage output, especially important when powering sensitive electronic devices.

Modern generator carburetors often include fine-tuning mechanisms that adapt to environmental conditions such as altitude or humidity. These adjustments are not just conveniences—they're necessary for avoiding premature engine wear or power inconsistency. Whether you're operating in humid coastal regions or dry high-altitude zones, the carburetor responds dynamically to changing conditions.

Starting and Idling Stability

Starting a generator in cold weather or after long periods of inactivity can be challenging. A high-quality carburetor with well-engineered choke functionality ensures smoother cold starts and faster transitions to idle. This stability reduces engine strain and lowers emissions during startup. An efficient idle setting also means less fuel consumption when the generator is running on standby mode.

If a generator frequently stalls or fails to idle correctly, it’s often a sign of carburetor malfunction or contamination. Upgrading to a better carburetor can resolve such issues and restore the generator to factory-like performance.

Key Benefits of Using a High-Quality Carburetor

Improved Engine Longevity

Engines operating with precise air-fuel ratios burn fuel more efficiently and generate less residue. This clean combustion process results in fewer deposits on valves, pistons, and cylinder walls. Over time, this contributes to reduced engine wear and longer intervals between maintenance. Investing in a premium carburetor is, in effect, investing in the lifespan of your generator engine.

Reduced wear also translates into lower vibration and smoother operation. When internal engine components experience less resistance and friction, the overall durability of the unit improves, especially under continuous or high-load conditions.

Enhanced Fuel Economy

Generators can consume a significant amount of fuel during extended power outages or remote operations. A high-quality carburetor delivers optimized fuel usage, minimizing waste and extending the runtime per tank. Especially in off-grid scenarios, every drop of fuel matters. By selecting a carburetor designed for efficiency, users can experience noticeable savings in fuel costs over time.

The carburetor’s ability to maintain consistent mixture levels at varying loads ensures the generator doesn’t overcompensate with excessive fuel delivery. This translates into real-world fuel efficiency, especially during fluctuating power demands.

Recognizing When to Replace a Generator Carburetor

Common Performance Issues

Frequent misfires, hard starts, or surging behavior are telltale signs that the existing carburetor is no longer performing optimally. These issues may arise due to internal clogs, gummed-up jets, or diaphragm failure—particularly if the generator has been stored for long periods without fuel stabilization. Rather than relying on repeated cleaning, many users find long-term success by replacing the old carburetor with a newer, higher-performing model.

Other symptoms include black smoke from the exhaust, inconsistent voltage output, or poor throttle response under load. Each of these points to combustion imbalance, which often stems from carburetor degradation.

Maintenance vs. Replacement

Routine maintenance—such as draining fuel after use, using stabilizers, and cleaning jets—can extend a carburetor's life. However, even with meticulous upkeep, materials can degrade, especially under ethanol-blended fuels. Replacing the carburetor becomes a cost-effective alternative to more expensive engine repairs.

When evaluating whether to clean or replace, consider the time and effort required for disassembly and reassembly, availability of parts, and long-term generator usage. In many cases, replacement with a modern carburetor that fits your generator model offers immediate and lasting benefits.

Choosing the Right Carburetor for Your Generator

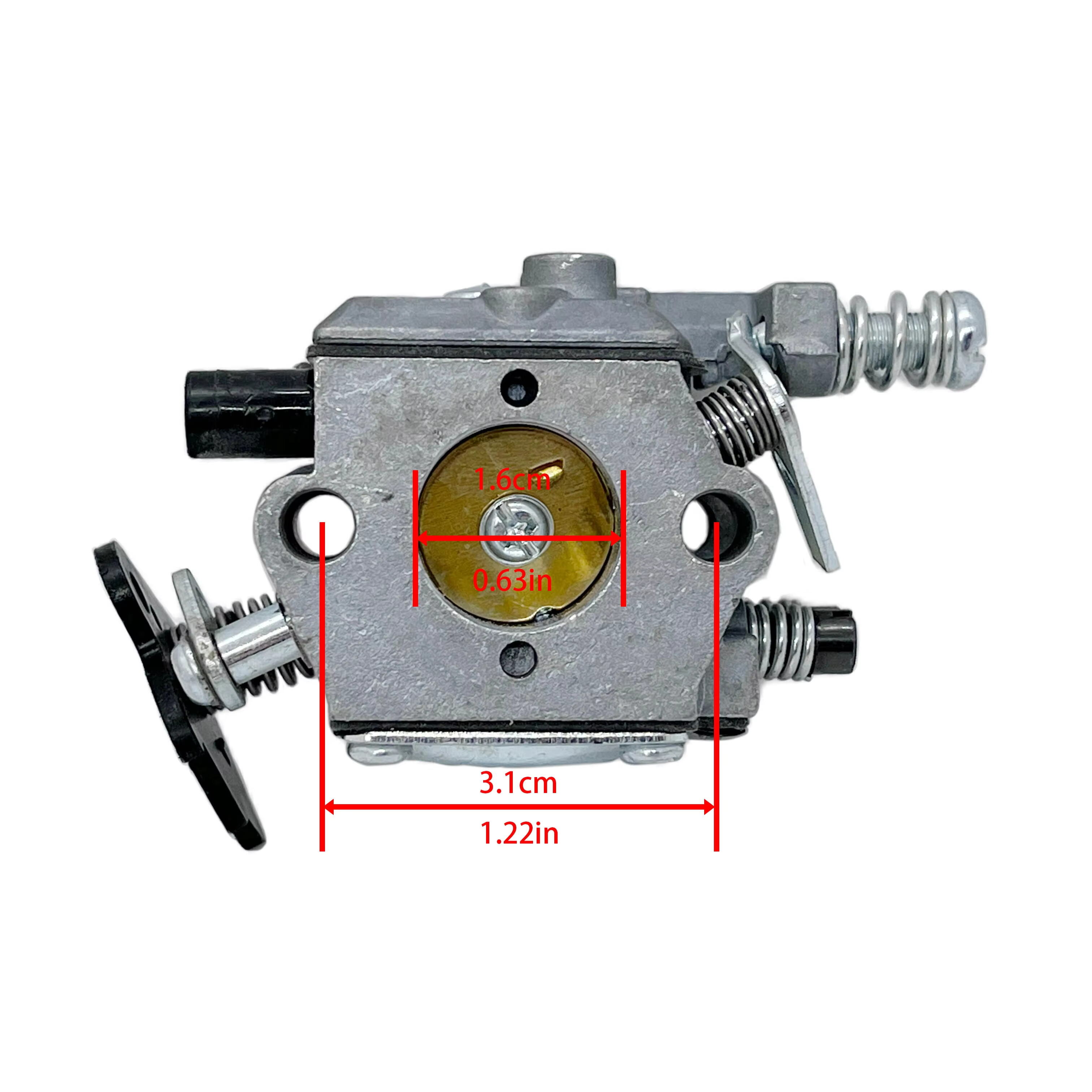

Compatibility and Sizing

Not all carburetors are interchangeable. It’s essential to choose a unit specifically designed for your generator’s make and model. Factors like mounting hole spacing, throttle linkage configuration, and float bowl orientation can affect installation and performance. Before purchasing, cross-reference OEM part numbers or consult your generator's manual to ensure compatibility.

Some aftermarket carburetors offer adjustable jets or come with conversion kits to fit a range of models. These can provide greater flexibility, but users must verify performance under different loads before relying on them for critical power tasks.

Material and Build Quality

High-quality carburetors often feature metal components that resist warping, corrosion, and wear over time. Brass jets, stainless-steel linkages, and machined housings all contribute to reliability and consistency. Plastic-bodied carburetors, while affordable, may suffer under high-heat conditions and should be reserved for short-term or low-output applications.

Additionally, check for carburetors with fuel drain plugs, accessible choke controls, and removable bowls, which simplify maintenance and extend usability.

Advanced Features to Look For

Adjustable Jets and Mixture Screws

Adjustability is critical for fine-tuning generator performance under varying loads and altitudes. Some carburetors allow access to both idle and high-speed jets, making it easier to tailor combustion behavior to your environment. This feature is especially useful for generators used in camping, mobile workshops, or regions with significant elevation changes.

In industrial use cases, adjustable mixture screws help accommodate variable fuel qualities and ensure consistent engine response even under heavy demand.

Integrated Fuel Shut-Off and Drain Systems

Premium carburetors often include built-in fuel shut-off valves or drain ports, allowing users to empty fuel before storage. This prevents gumming and varnishing—common causes of carburetor failure. These small design additions save time and prevent damage, particularly in seasonal or emergency-only generators.

By draining residual fuel from the float bowl, users can greatly reduce the chances of buildup, especially when storing the generator during winter months.

Impact on Generator Performance and Reliability

Consistent Voltage Output

Stable engine operation driven by a quality carburetor ensures your generator delivers reliable voltage, which is critical for electronics and sensitive appliances. Fluctuating voltage due to poor fuel mixing can damage connected equipment and reduce generator life. A smooth-running carburetor keeps output steady even as demand fluctuates.

This is particularly important for backup systems that support medical equipment, servers, or HVAC systems. The carburetor’s reliability directly affects the generator’s trustworthiness during emergencies.

Reduced Maintenance Downtime

By keeping the engine clean internally, a good carburetor minimizes the need for frequent oil changes, spark plug replacements, or valve cleanings. This allows the generator to run for longer periods between service intervals, which is particularly valuable for businesses relying on constant uptime.

Contractors, farmers, and remote site operators especially benefit from fewer breakdowns and lower long-term operating costs.

Long-Term Value of Investing in a Premium Carburetor

Total Cost of Ownership Reduction

While high-quality carburetors may cost more upfront, their extended lifespan and performance benefits justify the investment. Fewer breakdowns, improved fuel usage, and extended engine life lead to a lower total cost of ownership. Compared to repeated tune-ups or premature generator replacement, a one-time carburetor upgrade is often the smarter choice.

Especially in high-demand or mission-critical applications, reliability trumps initial cost considerations. A premium carburetor ensures your generator is always ready when needed.

Environmental and Operational Efficiency

Efficient combustion results in cleaner emissions, aligning with growing environmental regulations and sustainability goals. Less unburnt fuel also means fewer smells, reduced carbon monoxide output, and less environmental impact—important for both residential users and commercial operators in regulated industries.

For operations in urban areas or near residential zones, having a quiet, clean-burning generator supported by a quality carburetor can be a key selling point or regulatory requirement.

FAQ

How do I know if my carburetor needs replacement?

Common signs include hard starts, poor idling, black smoke from the exhaust, or surging engine behavior. If cleaning doesn't solve the issue, replacement may be necessary.

Can I install a new carburetor myself?

Yes, many carburetors are designed for user-friendly installation. However, always ensure compatibility with your generator model and consult the manual for proper procedures.

What materials are best in a high-quality carburetor?

Look for carburetors made with brass jets, aluminum or stainless-steel housings, and steel linkages. These materials offer superior durability compared to plastic alternatives.

Will a new carburetor improve my generator’s fuel efficiency?

Yes, an efficient carburetor delivers the correct air-fuel mixture, reducing waste and optimizing fuel use. Over time, this results in lower operational costs and extended runtime.

Table of Contents

- Enhancing Engine Efficiency Through Precision Fuel Mixing

- Understanding the Role of a Generator Carburetor

- Key Benefits of Using a High-Quality Carburetor

- Recognizing When to Replace a Generator Carburetor

- Choosing the Right Carburetor for Your Generator

- Advanced Features to Look For

- Impact on Generator Performance and Reliability

- Long-Term Value of Investing in a Premium Carburetor

- FAQ