Mastering the Chainsaw: The Role of Carburetors

Mastering the Chainsaw: The Role of Carburetors

Introduction

Chainsaws are super high powered machines that have transformed the world of foresters and landscapers. They are really quite fast at cutting down tress, as well trimming down branches and shaping hedges. Every Chainsaw has an engine at its core and within that engine, is a carburetor which determines the functionality of your chainsaw. Such a thing is that the understanding of chainsaw carburetors, which can be greatly beneficial if you want to know how your operator works beforehand; whether for good operating potential in general time and efficiency improvement. We will examine in more detail why the chainsaw carburetor is important, what effect its operation has on performance.

Know Your Carburetor (Chainsaw)

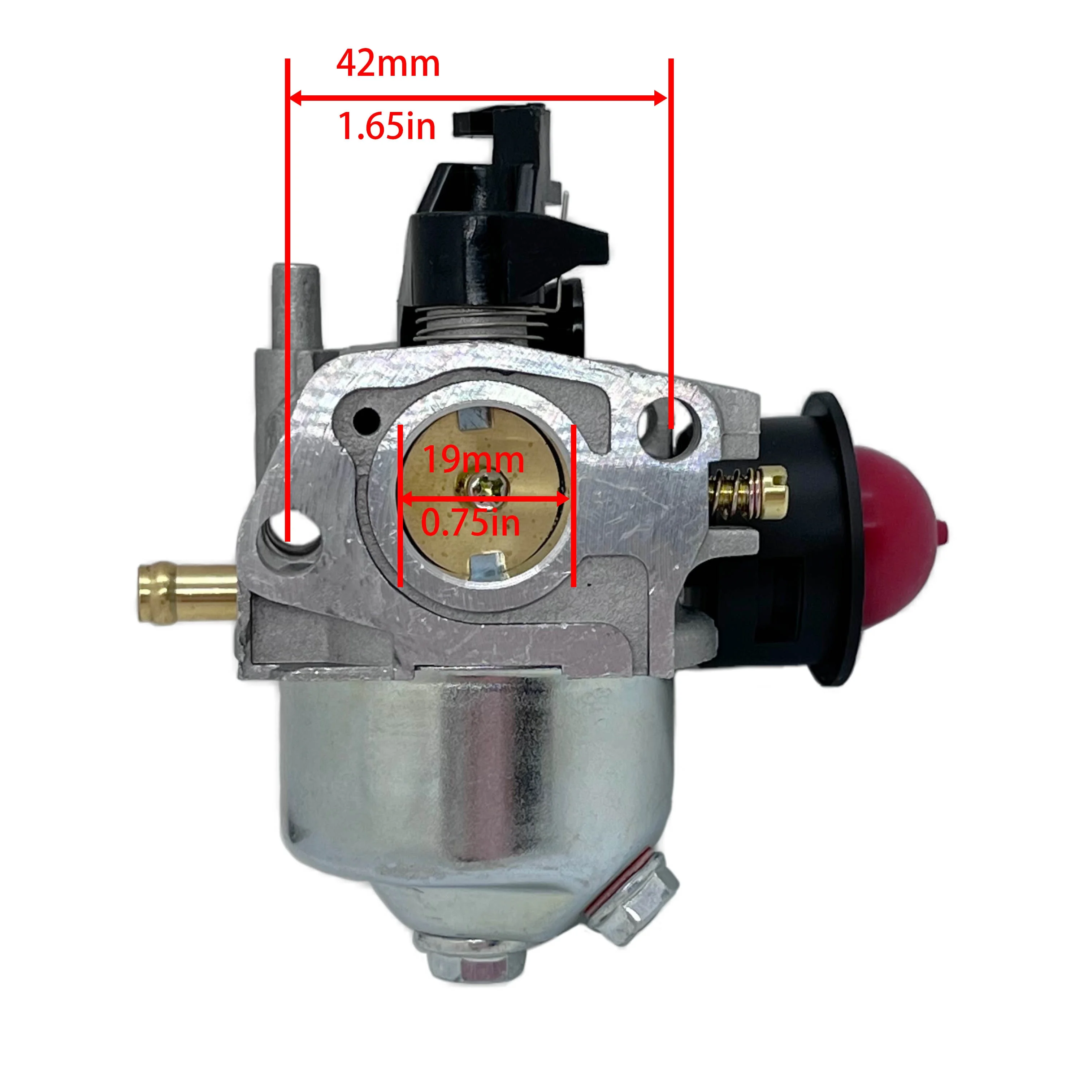

The carburetor in a chainsaw is the part where air and fuel mix for combustion. That mix is sent into the engine's cylinders, where a controlled explosion turns it into shaft horsepower to spin whatever part of the chainsaw chain isn't already stuck six inches deep in rotten wood. The design and state of the carburetor have direct effects on engine performance, mileage, emissions.

The two types of carburetors used in the chain Saws

There are a lot of different models of carburetors that work on various chainsaw engines, and all have their specific individual features.

Types of diaphragm carburetor Simple and Reliable These types of pumps are a bit smoother in terms of operation but they do use more parts and need to be checked up on quite regularly.

Float-type carburetors rely on a float to keep fuel heights in check which means it provides predictable goodness consumption however those are relatively more likely to get jammed and may require detoxification frequently.

Electronic fuel injection (EFI) systems allow precise control over the amount of fuel being used, which means that it's easier to tune and clean air-fuel ratio compared with a traditional carburetor. Most premium chainsaws and professional-grade machines have some sort of vibration dampening system implemented.

Carburetor Performance Factor

What effects the performance of a chainsaw carburetor

The air-fuel mixing ratio is important for the combustion process to function efficiently And if you get it wrong the mixture can be a killer.

The choke system that the fuel mixture with cold start and smooth operation is important.

On the trail: You may need to readjust for environmental factors such as altitude, temperature and other external conditions that might impinge upon the topographical landscape in order not to affect proper operation of components within your carburetor.

Dirt and debris leading to a clog in the carburetor which can interfere its ability of delivering an appropriate air-fuel mixture also ultimately causes poor engine performance.

Prevention and Solution

A chainsaw carburetor should be properly maintained which an owner can do themselves:

Regular cleaning and maintenance will help prevent clogs, ensuring the gate works smoothly. Test the filter of air and cleansing jets on carburetor

Adjust the air-fuel mixture to increase engine performance and maximum power, increases fuel efficiency.

Common problems such as flooding and starting (poor driveability) are usually fixable by cleaning the carburetor, or adjusting air/fuel mixture. Nonetheless, if the engine will not run properly in any condition it may be a sign that you need to either rebuild or replace your carburetor.

Setting the Carb Up Perfectly

Tuning of the carburetor means making adjustments to get the most performance. Such settings might involve turning the idle speed screw, and aligning throttle plates so that engine speeds change without jerking or hesitating. A properly adjusted carburetor enables the saw to produce more power and acceleration, while it also increases fuel efficiency from consuming less gas or oil, burns fumes cleaner for lower emissions.

Environmental Considerations

This can be particularly important reading: "Exploded View" Dirt Rider These chainsaw carburetor emissions may have an environmental impact, especially in sensitive locations. Technologies such as EFI systems are attempts to reduce emissions and increase fuel consumption by improving carburetors. Equally, the practice of how to operate a chainsaw sustainably by maintaining it well and ensuring that only correct fuel is used also helps in reducing an environmental footprint.

Conclusion

One of the main components on it is a carburetor, which directly affects performance qualities, resource and efficiency. Operating at peak efficiency All chainsaw users need to know how carburetors work and the basic tasks of maintenance, but what many ignore is that tuning can also optimize engine performance. Taking time to learn and properly maintain your chainsaw's carburetor will ensure you have a reliable piece of cutting equipment that is capable of handling even the most demanding forestry and landscaping tasks.